Mar 13 2005, 02:29 PM

As fate would have it, my first commission is from Stephen

Bright, the fellow who bought my Ramirez 1a 10-string classical.

He loves the 10-string so much, he asked me to build him another.

Well, given the fact that I haven't built one yet, and also that

I sort of miss my old Ramirez, I decided to build two. The first

one will be the guinea pig, as it were. The second will be Stephen's.

I intend to document both builds here.

In case you're wondering what on Earth a 10-string is, here

are a couple of shots of my old Ramirez:

A bit of history -- the 10-string guitar is a result of a

collaborative effort between Narciso Yepes (1927-1997) and Jose

Ramirez III (1922-1995). The first modern 10-string classical

was built by Ramirez in 1964. It has always been somethng of

an obscure instrument, with Yepes having been, by far, its largest

proponent. In more recent years, however, it has been slowly

gaining in popularity, chiefly among players who wish to transcribe

baroque or renaissance lute music to the guitar, where the full

range of bass lines can be preserved. In a similar respect, a

growing number of arrangements of pieces originally written for

piano or harpsichord is also becoming available. Also, players

are becoming more inventive with respect to tunings, which has

fuirther enhanced the repertory.

Actually, except for the neck, fingerboard and bridge, a 10-string

is not substantially different from a 6-string classical. Finding

wood of the correct size can be a bit of a problem, but fortunately

Grant came through with the mahogany and ebony I need for the

necks, and Eddie Yohannes, another member here, was able to supply

me with oversize bridge blanks. Oh, and I can't leave out Mark

(Manitou) for supplying me with a nice piece of corian from which

I'll be able to cut the oversize nuts and bridge saddles. A shame

-- that piece of corian is almost too pretty to cut.

Why Corian? A couple of reasons -- even though it is a type of

synthetic stone, it works easier than bone, and it doesn't stink.

I can cut it with my bandsaw and machine it in my milling machine.

I've used Corian on all my builds so far, and I think it compares

quite favorably with bone in terms of tone and sustain.

As for the woods I will be using, for the first build, I have

selected a nice top set that I cut from a billet I obtained from

Mario. Not sure which tree it is -- I think he called it his

"son of 70203." I have a very nice back and side set

of Bolivian rosewood that I obtained almost a year ago. Great

tap tone. Stephen is supplying his own tonewood for the second

build -- a German spruce top set and a Brazilian rosewood back

and side set.

I've begun work on the 1st guitar already. Joined and thicknessed

the top, installed the rosette and cut the soundhole. Bent sides.

BTW, Bolivian rw is at least as easy to bend as walnut. Easier

to bend than Indian rw. I like it a lot. Glad I'm not allergic

to it

Best, Michael

Mar 13 2005, 04:59 PM

I should add that I've built only one steel string acoustic to

date using corian, and it sounds fine to me. The fact that all

the others use nylon strings may have something to do with it.

Perhaps the difference between the two substances is not as critical

with nylon strings. I guess the best way for me to find out for

sure would be to make nuts and saddles from each material for

the same guitar and A-B them.

As for finding the time -- fortunately -- or unfortunately, as

the case may be -- I have quite a bit of time on my hands, and

lutherie has been an excellent way to keep myself busy. Hopefully

some day soon, it'll start help paying the bills -- or the kid's

college tuition (four years and counting -- *shudder*).

As for playability, welp, that's a whole area of discussion.

The above Ramirez is not a particularly easy guitar to play.

But that is because of its string length, not the additional

strings. Back when I bought that guitar, Ramirez was building

its 1a models with a 664mm (26.1") string length. I have

medium-sized hands, and I found the string length uncomfortable.

But it's all relative, you know? Narciso Yepes, whom I had the

pleasure to meet in 1975, was a tiny guy with small hands, yet

he played a 664mm Ramirez for many years.

Still, I prefer 650mm. Stephen and I have not yet nailed down

the string length for his guitar, although I'm thinking he's

leaning toward 660mm. But he's a big guy with long fingers, so

a longer string length might actually be more comfortable for

him.

It takes a little getting used to, when one first begins playing

a 10-string. Classical technique dictates a "precision grip"

with the left hand, i.e., no hooking the thumb around the neck,

so because of this, neck width is not that big of an issue. The

bigger problem is the unconscious desire to center ones hand

on the fingerboard. When I first acquired my 10-string, it took

a good two-weeks of getting used to before I was comfortable

sighting down that long row of strings, and getting used to planting

my hands down toward the bottom six, rather than in the middle.

For quite a few years, 5-on-a-side classical tuners were simply

not available, so what Ramirez did was to cut sets and butt them

together. Stephen has ordered a set of 5-on-a-side tuners made

by Alessi. I have decided to use the individual Gilberts, a set

of 10 being somewhat cheaper than the Alessis, and certainly

of equivalent quality, if not perhaps a bit better.

Thanks for the heads-up on the Brazilian. I have one set in my

stash, but I've never worked with it. Would you recommend soaking

the sides before bending them? I'm somewhat concerned about getting

chip-out when routing the back for the binding.

Best, Michael

Mar 15 2005, 01:56 PM

I've gotten in the habit of referring to my guitars by build

number. The first of these two 10-strings is number 8, the second

will be, obviously, number 9. Just so's you know what I'm taking

about.

I've been working on number 8's top waiting on my wood order

from Grant. Yesterday I got about as far as I could take it prior

to fitting the neck. Here's what the top looks like so far:

I'll be using flying tone bars, similar to those I installed

on number 6, but they will not be installed until after the sides

are in place.

Incidentally, I'll be working from a set of Contreras plans for

number 9, so its top bracing will be entirely different.

One difference between 10-string and 6-string construction that

I realized right off the bat when laying out the dimensions on

this top is that because of the extra width of the neck, the

12th fret is moved bridgeward about 0.1":

This requires that the saddle line be similarly offset. I

elected not to adjust the position of the soundhole. Normally

this would result in a couple of very small 19th fret remnants

because the 12th fret would be positioned closer to the soundhole

than on a regular 6-string, but because of the extra fingerboard

width, it will actually overlap the edge of the soundhole. So

there should be no detriment. The wood I ordered from Grant arrived

today:

Grant was nice enough even to lay out the fingerboard outlines

on the ebony to insure it was of adequate size. Nice looking

wood, I gotta say. You can see in the above photo what I mean

by the fingerboard overlapping the soundhole, which will give

me the opportunity to run an extension if I choose. Most 10-strings

have at least an extra fret. I'm gonna see if I can add three.

That'll give the player a high D.

Yes, each guitar is going to need three pieces of mahogany. The

piece of ebony off to the left side will be cut into two 20"

strips and each will be laminated between two of the mahogany

blanks. The other two blanks will be used for stacked heels.

I'll have a fair amount of leftover wood from this process, some

of which I plan to use for back bracing.

We have guests arriving from Taiwan later today, so right now

we're getting our tired old house cleaned up. Pretty soon, it'll

be time for me to drive out to the airport, so I doubt I'll be

getting to do much of anything with this great looking wood until

tomorrow at the earliest.

Stay tuned. Best, Michael

Mar 17 2005, 01:08 AM

Today I began the most challenging part of a 10-string build

-- fabricating the neck. I have lain in bed at night thinking

through how I would proceed with the neck for weeks, and have

largely worked out in my head how I wanted to do it.

I suspect that the way I'm building these necks is different

from the way most other classical builders who add center reinforcing

strips do it. I'm guessing that Ramirez and others route a channel

for it in the neck blank, not unlike the way one would route

a channel for a truss rod. But if you look at the above photo

of my old Ramirez, you'll note that the reinforcement strip is

covered by the headstock's scarf joing and the heel block, which

means that the strip was inlaid after cutting the scarf, but

before gluing up the headstock and the heel.

Well, I'm not doing that. These guitars will have three-piece

laminated necks. I wanted the ebony strip to butt up against

the underside of the fingerboard, forming a "T" for

max ridigity, but I did not want to carry the lamination through

the headstock and the heel -- I wanted to preserve the more traditional

look as much as possible. This complicated things. My early estimates

are that, in order to do the neck the way I want it, this will

add at least an entire day's work to the build time.

OK, first things first. I decided to cut out the ebony strip

to its approximate dimensions and thickness it to about 0.280".

Next, I squared up and thicknessed the two neck blank pieces.

They required a bit of final touching up with the plane to make

a nice even fit with the center strip:

Then I cut the scarf for each neck blank half and planed each

half with its half of a headstock the way one normally would.

It occurred to me after doing this that this is a wasted step.

The scarf joint must be planed true again after gluing together

the laminates and before gluing the headstock and shaft together.

Next, I trimmed the same 15 degree angle into the ebony center

strip. Here are the three pieces mated up dry:

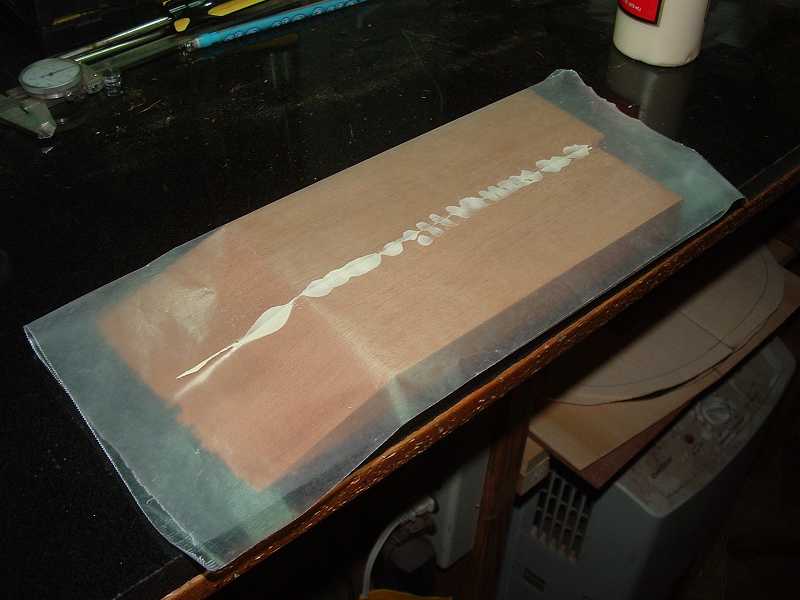

Laid out some wax paper, applied the glue, and covered with

wax paper:

Clamped it all down good using one of the neck blank pieces

as a caul:

Did the same with the headstock section:

Here's the glued up neck shaft with the fingerboard alongside:

And another look at the blank with the neck's actual dimensions

penciled in. As you can see, there will be a fair amount of offcut

material.:

So far, so good. Tomorrow, final smoothing and fitting of

the scarf, then glue-up.

Best, Michael

Mar 18 2005, 01:01 AM

Today, I trimmed the edges of the neck blank down to the same

width as the headstock by running it through my bandsaw and then

doing the final contour with a block plane. This made it easier

to clamp up the two pieces so I could plane the scarf joint before

gluing. You guys who have your table saws set up for this procedure

are miles ahead of me in the ease department. I'm having to fit

all this by hand. I don't trust my funky old benchtop table saw

to do this well enough for lutherie.

Gluing up the scarf joint is really no different from gluing

it up with any other build, just everything is a bit wider. I

always use five clamps at the joint, one for each corner and

another for the middle.

Another aspect of the 10-string neck that must be taken under

consideration when laying out the dimensions before cutting wood

is the extra length of the headstock that is required to support

five-on-a-side classical tuners. The standard center-to-center

distance between tuners is 35mm or 1.378". A 10-string has

two additional tuners per side, so the headstock must be at least

70mm or 2.756" longer to accomodate them. I follow Cumpiano's

book when it comes to sizing the headstock -- 8" in length.

So to keep things simple, I just added 3" to the length

of the headstock before cutting the scarf joint.

Here is the neck shaft after glue up. You should be able to

see a roughly penciled in outline of the headstock.

Here is a rear view look at the neck shaft. I've duplicated

the "look" of the center reinforcing strip as used

by Ramirez, Kohno, Navarro and others, by covering it with the

headstock section, yet my construction will be stronger since

the ebony strip runs all the way through the neck shaft. (edited)

After cutting the fingerboard to its rough contours, I began

to mark out its outlines with a bit more precision. It looks

like I might just barely be able to squeeze in 22 frets. The

horizontal lines drawn onto the fingerboard represent the 18th

through 22nd frets.

Tomorrow, I begin to assemble the pieces for the stacked heel.

That should be another adventure

Best, Michael

Mar 18 2005, 05:46 AM

Michael,

Wow, this is quite a project. Almost as crazy as a harp guitar!

Not being familiar with classical guitar construction, I didn't

quite understand your statement, "Here is a rear view look

at the neck shaft. I've duplicated the "look" of the

center reinforcing strip as used by Ramirez, Kohno, Navarro and

others, by covering it with the headstock section, yet my construction

will be stronger since the ebony strip runs all the way through

the fingerboard." Could you elaborate?

David

Mar 18 2005, 10:35 AM

Hi David,

Ah, I think I now understand your question -- after I wrote all

the stuff below I should have written "neck shaft"

instead of "fingerboard." That is, I should have stated,

"I've duplicated the "look" of the center reinforcing

strip as used by Ramirez, Kohno, Navarro and others, by covering

it with the headstock section, yet my construction will be stronger

since the ebony strip runs all the way through the neck shaft."

Think I'll go edit that post so nobody else gets confused.

Just in case this wasn't what confused you, I'm leaving in this

note the stuff I typed already:

Yeah what I meant by that is I'm pretty sure -- not absolutely

positive -- that Ramirez, Kohno, Navarro and others cut a channel

in the back side of the neck shaft for an ebony reinforcement

strip. Not just in 10-strings, but in all their guitars. I dunno

how deep their reinforcement strips are, but I don't think they

do the laminations that I've done -- they just cut a channel

and inlay the strip. I say this because the grain in the neck

shaft appears to indicate that it is a single piece of wood.

So, if this is indeed the case, the process is 1) cut the scarf,

2) route the neck shaft for the inlay strip, 3) level the strip

flush to the shaft, and 4) glue down the headstock and heel.

The result is the way the back of the Ramirez neck looks in the

photos I show at the beginning of this thread, where the strip

is covered by the headstock and heel.

I wanted to duplicate this appearance -- that is, I didn't want

the ebony strip running up the backside of the headstock and

through the heel. It would have been much easier just to laminate

a strip of ebony down the whole blank before cutting the scarf,

but then I would have had the strip showing at the back of the

headstock.

Best, Michael

Apr 1 2005, 09:08 AM

WB,

I'm not planning to change the bracing at all. The large fingerboard,

and a larger "foot" section of the neck heel block,

plus the longer bridge, seems to provide more than enough additional

stiffness for the extra four strings.

My apologies for not posting any recent updates on this project.

Been really busy with other matters this past couple of weeks.

I've made some progress, though. Glued down the heel blocks for

both guitars, and roughed in the heel shape on #8. Pics to follow

soon.

Best, Michael

Apr 21 2005, 03:59 PM

Welp, things have finally started to settle down over

here. Life is still kinda hectic, but at least I've been able

to make some headway on the 10-strings. So, it's time to bring

y'all up to date.

These extra wide necks have given me more troubles than I originally

thought they would. Most of this is due to the fact that I have

only one vise that is big enough to hold a 6" width, and

it isn't a very good one. So I got the idea to lightly glue on

a couple of sacrificial pieces of hardwood to the top and bottom

sides of the neck shaft, because I could clamp the vise on them

rather than the entire width of the shaft. Here's a photo I took

while gluing a piece on:

This worked -- sort of. Couple of times, the wood broke loose

at the joints. The glue didn't fail, though -- the wood did.

Too small of a cross-sectional area for the forces I was applying

(chiseling the neck heel).

Cumpiano shows very clearly how to do a stacked heel, and this

is the way I prefer to do it. But with the 10-strings, I had

to modify the process. Here's a shot of the neck shaft with the

heel pieces fitted up dry. The two pieces laying against the

neck shaft were already glued together separately before I took

this photo.

I glued the two doubled up pieces to the shaft first, and

then glued the remainder of the heel pieces together, then finally

glued everything together

I didn't have a 10-string handy to refer to, and noted only

after the fact that I should have offset the bottom piece by

about 2" toward the soundhole. Reason is that most 10-strings

have larger "feet" than traditional classicals. So,

to make up for this, I had to go and glue on an extention. The

glue line will show, just barely, and it should be plenty strong

enough.

Here's a shot of guitar 8's heel after I've roughed in the shape.

It still needs a fair amount of material removed yet, but I'm

getting close.

And a shot of the wedge technique I picked up from Rik Middleton.

I like cutting wedges way better than cutting side slots. So

much easier.

This is the way guitar 8's neck looks right now. Next step

is to glue down the headstock veneers and headplate, then drill

the tuner holes and cut the slots. After all that I can begin

contouring the neck.

Meanwhile, I've bent guitar 8's sides and joined the back

set. Tell you what, I really like working with Bolivian rosewood.

Now, I know that some folks have an allergic reaction to it --

which is a pity, really. This wood is at least as easy to bend

as walnut, smells just like rosewood, has a great tap tone, and

even looks nice!

Here's a couple of mock-up shots of what the box will look like

soon.

A close up of guitar 8's joined back set.

And lastly, a close up of guitar 9's back set. Brazilian. Unfortunately,

Stephen got it pre-cut, so I'll have nothing extra for making

a headplate from, but we've come up with a workaround for that.

That's it for now.

Best, Michael

Apr 22 2005, 07:28 PM

Michael,

Like the looks of that Bolivian RW, pitty I can't use it. Your

placement of the white stripes is excellent too.

Good solution on the too small vice. With care, you will get

the blocks off the neck with no damage. I think violin makers

use this technique quite often. Usually though we read that they

use a thinned down or reduced strength hyde glue. I doubt they

are putting their thinned joints thru the stress you apply though.

I got my 6" machinist vice from Home Depot for about $36.

You don't need the high end vice for holding wood.

So you need a Brazillion RW head plate 11" long? I'll look,

but don't think I have anything that long. Most of my BRW is

shorter or too narrow.

Could you use ebony in the center with BRW on the edge? You might

even find some cocobolo that will look like Brazillion. Those

back pieces for the Brazillion guitar you show are quite dark.

Nice.

Steve

NEXT

PAGE / PAGE 1 / PAGE 2 / PAGE 3 / PAGE

4 / PAGE 5 / PAGE

6 / PAGE 7 / PAGE

8

Home / Articles

/ Gallery / Accessories

/ Builders / Composers

/ Guitarists / Movies

/ Sheet Music / Free

PDFs / Recordings / Teachers

/ Radio / Join

/ Contact Us